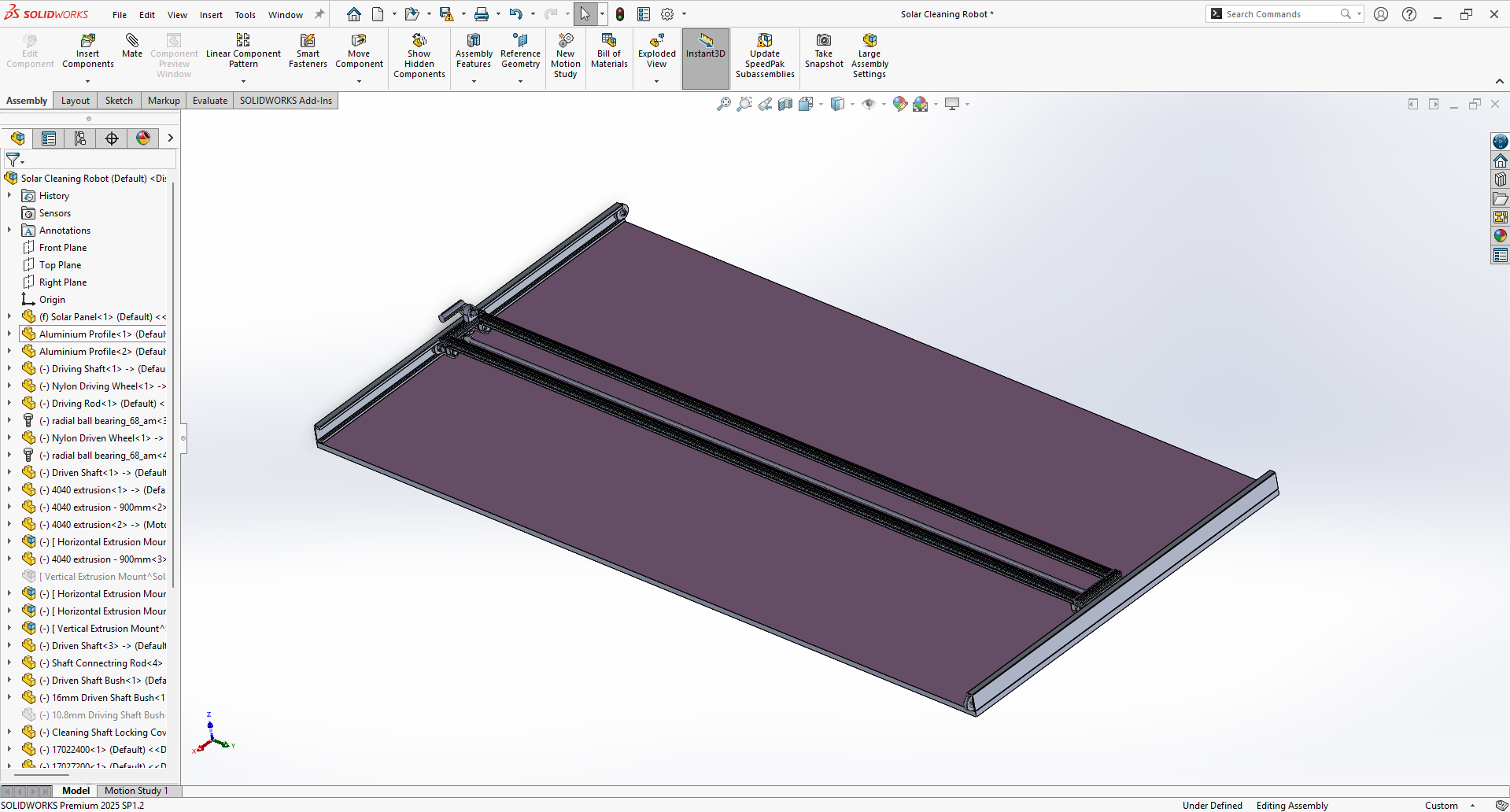

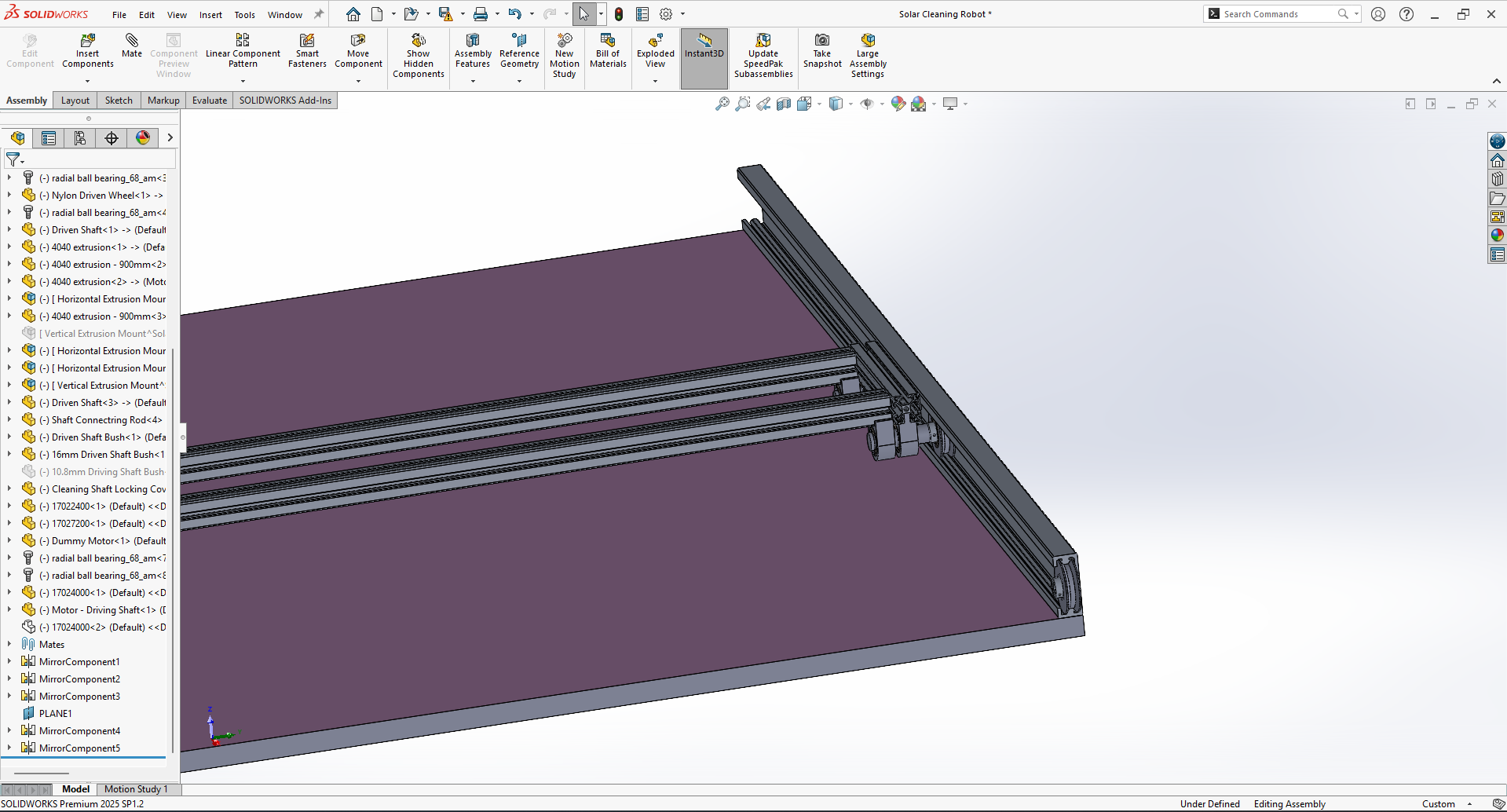

A lightweight, modular robot designed for automated cleaning of solar panels in renewable energy farms. The system uses a Sigma-based guiding channel for smooth pathing, making it space-efficient, easy to deploy, and adaptable to various panel sizes.

This Solar Cleaning Robot was developed for a renewable energy company to automate maintenance of utility-scale and rooftop solar arrays. The brief demanded a solution that was lightweight, physically compact for storage and transport, modular across a range of panel sizes and pitches, and that intentionally avoided complex drive trains to minimize maintenance in harsh outdoor conditions. The design centers on reliability and easy serviceability while maintaining consistent cleaning performance.

We designed a custom Sigma-based guiding channel to control travel path over panels, eliminating the need for differential traction systems and complex steering. The chassis uses lightweight aluminum and polymer composites to meet the weight limit while keeping the center of gravity low. A modular mounting/adapter kit was created so the same robot could span small residential layouts up to large commercial arrays. The cleaning assembly employed a combination of soft brushes, micro-fibre pads and a controlled water/air delivery system tuned to avoid panel scratching and reduce water usage. Electrical systems were sealed to IP-grade standards, with easy access panels for field service and a simple plug-and-play telemetry module for remote health monitoring.

The robot delivered consistent cleaning across multiple panel geometries, reducing soiling losses and improving overall fleet energy yield. The simple mechanical pathing and modularity lowered maintenance overhead and spare-part inventories. The client reported easier scheduling of upkeep operations and measurable improvements in array efficiency, with the lightweight form factor simplifying on-site logistics and transport between installations.